Machining

Recommendations

WHAT IS TOOLOX?

Toolox® is a modern quenched and tempered prehardened engineering and tool steel, delivered with measured and guaranteed mechanical properties. The basic idea is to save you time by delivering Toolox heat treated and ready to use. It provides you with lower costs, reduced risks and saves you valuable time in your production process due to its excellent machinability. This combined with the benefit of working with the hardest prehardened tool steel in the world gives you a simple to use material with a wide variety of uses.

Toolox is based on the same low carbon content as in Hardox® and Strenx®, but it is specially developed for tools and machine components working at high temperatures. It has excellent fatigue properties, and you can increase the surface hardness with nitriding or PVD coatings to gain more control over the service life of your tools or components.

In the information that follows, you will find our recommendations of tools to process Toolox. Similar tools from other suppliers might work, but here are the ones we have tested so far.

SHORTER LEAD TIME FROM CONCEPT TO PRODUCTION

1. Your customer has an idea

2. Manufacturing

3. Transport

4. Quenching and tempering

5. Adjusting

6. Production

DRILLING RECOMMENDATIONS

HSS DRILLS

Use only HSS drills when you have unstable machine conditions. If the machine conditions are good you can use different solid/brazed cemented carbide drill or drills with exchangeable heads.

Use an HSS-Co drill (8% Co) with a low helix angle and a robust core that can withstand high torques.

Individual holes can be drilled with an ordinary HSS drill. For a rational production, either a microalloyed (HSS-E) or a Cobalt alloyed (HSS-Co) drill is recommended.

| METRIC (mm) |

Toolox 33 |

Toolox 40 |

Toolox 44 |

| Vc m/min |

~ 15 |

~ 9 |

~ 7 |

| Dc ( mm ) |

Feed rate ( mm/min and speed ( rpm ) |

| 5 |

0.10/950 |

0.05/570 |

0.05/445 |

| 10 |

0.10/475 |

0.10/290 |

0.09/220 |

| 15 |

0.16/325 |

0.16/190 |

0.15/150 |

| 20 |

0.23/235 |

0.22/150 |

0.20/110 |

| 25 |

0.30/195 |

0.28/110 |

0.25/90 |

| 30 |

0.35/165 |

0.35/90 |

0.30/75 |

| *35 |

0.40/136 |

0.40/80 |

0.35/63 |

| *40 |

0.45/119 |

0.45/70 |

0.40/55 |

| US (in.) |

Toolox 33 |

Toolox 40 |

Toolox 44 |

| Vc ft/min |

~ 50 |

~ 30 |

~ 23 |

| Dc ( in ) |

Feed rate (in./min) and speed (rpm) |

| 0.197 |

0.004 |

0.002 |

0.002 |

| 0.394 |

0.004 |

0.004 |

0.004 |

| 0.591 |

0.006 |

0.006 |

0.006 |

| 0.787 |

0.009 |

0.009 |

0.008 |

| 0.984 |

0.012 |

0.011 |

0.010 |

| 1.181 |

0.014 |

0.014 |

0.012 |

| 1.378 |

0.016 |

0.0016 |

0.014 |

| 1.575 |

0.018 |

0.018 |

0.016 |

* WHEN USING A LARGE DRILL DIAMETER ( >30 MM), MAKE SURE THAT:

- The machine is large and stable enough to raise sectinal forces.

- The spindle has zero play.

- The workpiece is well clamped.

- Motor output is equal to or greater than 7.5 kW.

ADVICE TO REDUCE VIBRATIONS AND INCREASE THE LIFETIME OF THE DRILL

- Minimize the distances to the column and between to drill tip and the workpiece

- Don ́t use a longer drill than necessary

- Always use metal supports

- Clamp securely

- Use a solid and firm table

- Always use coolant

- Coolant mix 8-10 %

- Just before the drill breaks through, disengage the feed rate for a second. Otherwise, play/springback can snap the drill tip. Re-engage the feed rate after the play/springback stops.

SOLID CEMENTED CARBIDE DRILL

For stable machine conditions and with internal

coolant. Coolant mix 8-10 % for all drilling.

| |

METRIC |

Toolox 33

65-90 |

Toolox 40

50-70 |

Toolox 44

40-65 |

| Diameter (mm) |

Vc ( m/min) |

| fn ( mm/rev ) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| 3.0 -5.0 |

0.08-0.15 |

0.10 |

0.06-0.12 |

0.08 |

0.06-0.11 |

0.07 |

| 5.01-10.0 |

0.09-0.16 |

0.12 |

0.08-0.15 |

0.11 |

0.08-0.13 |

0.10 |

| 10.01-15.0 |

0.16-0.22 |

0.18 |

0.14-0.20 |

0.16 |

0.12-0.18 |

0.15 |

| 15.01-20.0 |

0.22-0.28 |

0.25 |

0.16-0.24 |

0.20 |

0.16-0.20 |

0.18 |

*drilling 7x Dc, reduce the feed ~20 %

*drilling with external coolant ,reduce the speed and feed ~ 20 %

| |

US |

Toolox 33

213-295 |

Toolox 40

164-230 |

Toolox 44

131-213 |

| Diameter (in.) |

Vc (ft/min) |

| fn (in./rev) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| 0.118-0.197 |

0.003-0.006 |

0.004 |

0.002-0.005 |

0.003 |

0.002-0.004 |

0.003 |

| 0.197-0.394 |

0.004-0.006 |

0.005 |

0.003-0.006 |

0.004 |

0.003-0.005 |

0.004 |

| 0.394-0.591 |

0.006-0.009 |

0.007 |

0.006-0.008 |

0.006 |

0.005-0.007 |

0.006 |

| 0.591-0.787 |

0.009-0.011 |

0.0010 |

0.006-0.009 |

0.008 |

0.006-0.008 |

0.008 |

DRILLS WITH EXCHANGEABLE DRILL HEADS OR

BRAZED CEMENTED CARBIDE DRILL

For stable machine conditions and with internal coolant.

| |

METRIC |

Toolox 33

50-80 |

Toolox 40

50-65 |

Toolox 44

40-60 |

| Diameter (mm) |

Vc ( m/min ) |

| fn ( mm/rev ) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| 7.5-12.0 |

0.10-0.16 |

0.13 |

0.08-0.15 |

0.12 |

0.08-0.14 |

0.11 |

| 12.01-20.0 |

0.15-0.23 |

0.20 |

0.12-0.22 |

0.17 |

0.12-0.20 |

0.15 |

| 20.01-25.0 |

0.18-0.27 |

0.22 |

0.15-0.25 |

0.19 |

0.14-0.22 |

0.17 |

| 25.01-30.0 |

0.20-0.30 |

0.24 |

0.17-0.27 |

0.21 |

0.16-0.25 |

0.19 |

*Drilling with 25-30xD reduces the Feed rate by ~15-20 %

*The recommendation is to have at least 25 bar pressure on the waterpump.

| |

US |

Toolox 33

164-262 |

Toolox 40

164-213 |

Toolox 44

131-197 |

| Diameter (in.) |

Vc (ft/min) |

| fn (in./rev) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| 0.295-0.472 |

0.004-0.006 |

0.005 |

0.003-0.006 |

0.005 |

0.003-0.006 |

0.004 |

| 0.473-0.787 |

0.006-0.009 |

0.008 |

0.005-0.009 |

0.007 |

0.005-0.008 |

0.006 |

| 0.788-0.984 |

0.007-0.011 |

0.009 |

0.006-0.010 |

0.007 |

0.006-0.009 |

0.007 |

| 0.788-0.984 |

0.008-0.012 |

0.009 |

0.007-0.011 |

0.008 |

0.006-0.010 |

0.007 |

LONG HOLE DRILLING WITH 16-20xD

For stable machine conditions and with internal coolant.

| |

METRIC |

Toolox 33

50-70 |

Toolox 40

50-65 |

Toolox 44

40-60 |

| Diameter (mm) |

Vc ( m/min ) |

| fn ( mm/rev ) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| 6.0 |

0.12-0.16 |

0.14 |

0.10-0.15 |

0.12 |

0.08-0.14 |

0.11 |

| 8.0 |

0.14-0.20 |

0.16 |

0.11-0.18 |

0.14 |

0.10-0.18 |

0.13 |

| 10.0 |

0.17-0.24 |

0.19 |

0.13-0.22 |

0.16 |

0.12-0.21 |

0.15 |

| 12.0 |

0.18-0.26 |

0.20 |

0.15-0.24 |

0.18 |

0.14-0.23 |

0.17 |

* The cutting data on this page has been formulated in cooperation with Seco Tools.

| |

US |

Toolox 33

164-262 |

Toolox 40

164-213 |

Toolox 44

131-197 |

| Diameter (in.) |

Vc (ft/min) |

| fn (in./rev) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| 0.236 |

0.005-0.006 |

0.006 |

0.004-0.006 |

0.005 |

0.003-0.006 |

0.004 |

| 0.315 |

0.006-0.008 |

0.006 |

0.004-0.007 |

0.006 |

0.004-0.007 |

0.005 |

| 0.394 |

0.007-0.009 |

0.007 |

0.005-0.009 |

0.006 |

0.005-0.008 |

0.006 |

| 0.472 |

0.007-0.010 |

0.008 |

0.006-0.009 |

0.007 |

0.006-0.009 |

0.007 |

MILLING RECOMMENDATIONS

CLAMPING

Toolox has a very low level of residual stresses. To get the full effect make sure to use deformation-free clamping. If blanks are gas cut, mill off 5-10mm from the gas-cut edge to get a blank free from residual stresses.

The machinability of Toolox has been improved. During milling you will notice it because the chips produced are very bluish. We have modified the carbide morphology as compared to traditional tool steels, using less carbon in Toolox. Therefore, the heat generated during milling is transferred into the chip and not into the cutting edge/workpiece.

MILLING ADVICE

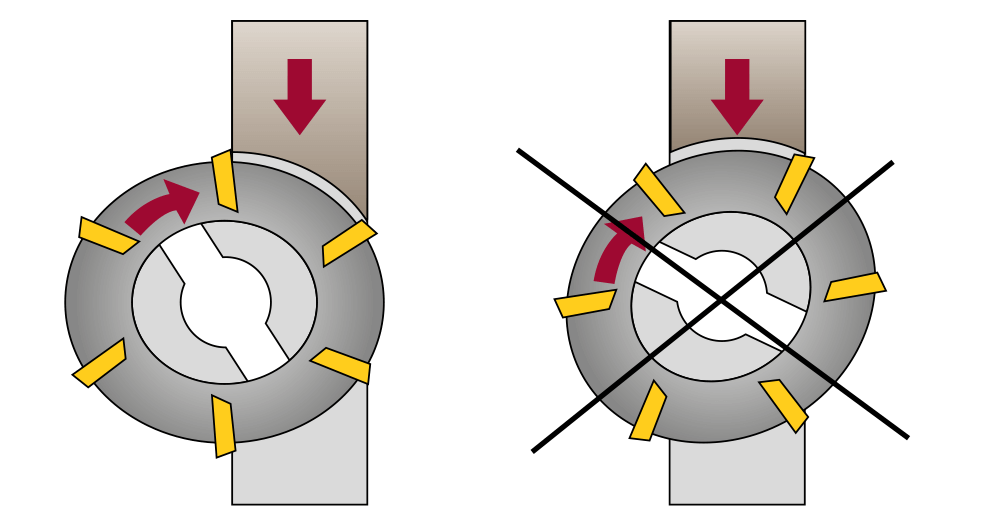

- Position the cutter off-center (to the left) to achieve a thicker chip at the entry and to avoid thick chip on the exit.

- Avoid cutting through the center line of the cutter, because this can generate vibration.

- Always use down milling (climb millIng).

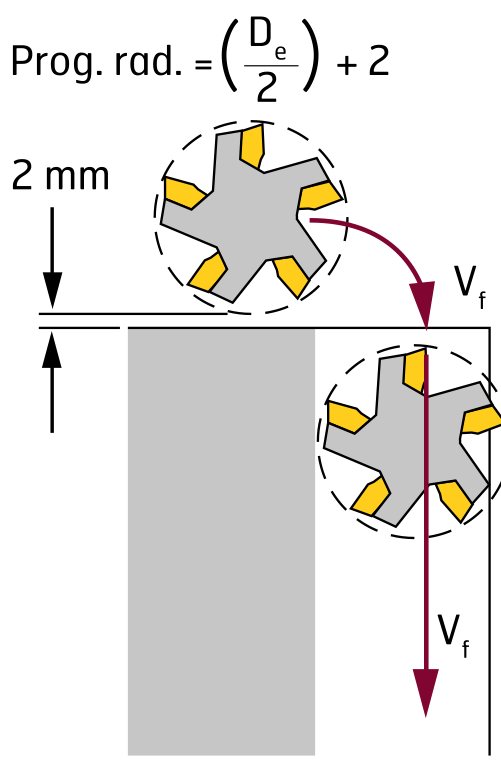

- The recommendation is that the radial engagement of the cutter (ae) should be 25 or 75-80% of the diameter.

If you enter the workpiece with the roll-into-cut method, the chip thickness on the exit is always zero, and it will help to give a longer tool life.

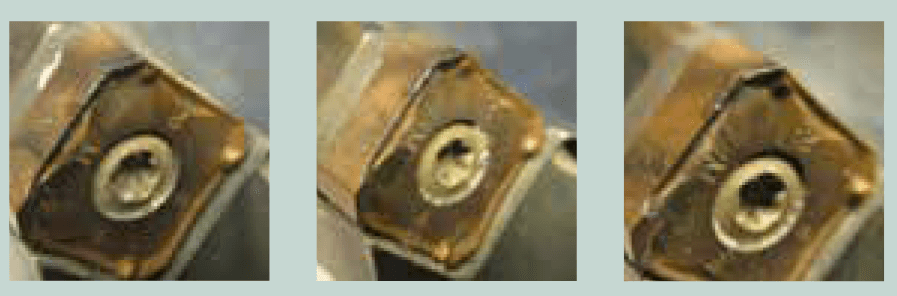

Roll-into-cut method

Wear after 800 passes

Straight into the workpiece

Wear after 390 passes

Roll-into-cut method

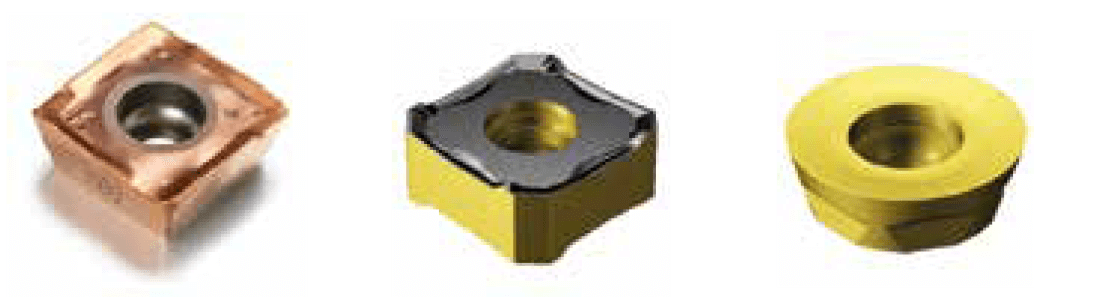

INSERT GRADES FOR MILLING

| P |

| ISO |

ANSI |

|

| 01 |

C8 |

|

| 10 |

C7 |

|

| 20 |

|

|

| 30 |

C6 |

|

| 40 |

|

|

| 50 |

C5 |

|

| M |

| 10 |

|

|

| 20 |

|

|

| 30 |

|

|

| 40 |

|

|

| K |

| 01 |

C4 |

|

| 10 |

C3 |

|

| 20 |

C2 |

|

| 30 |

C1 |

|

| 40 |

|

|

| H |

| 01 |

C4 |

|

| 10 |

C3 |

|

| 20 |

C2 |

|

| 30 |

C1 |

|

Wear resistance

Toughness

P ISO P= Steel

M ISO M= Stainless steel

K ISO K= Cast iron

K ISO H= Hardened stee

* Example insert grade 1030.

“The last 2 numbers in the insert grade indicate where in this scale the insert belongs, if the insert has wear or toughness resistance.“

INSERT GEOMETRY

The macro geometry affects many parameters in the cutting process. An insert with a strong cutting edge can work at higher loads, but it will also generate higher cutting forces, consume more power and generate more heat.

| Geometry |

| Parameter |

L |

M |

N |

| Edge strength |

|

| Cutting forces |

| Power consumption |

| Max chip thickness |

| Heat generated |

* Use insert grade P 30-50 with light cutting geometry and a coarse - pitch cutter if the machine power is low and with unstable machine conditions.

TURNING RECOMMENDATIONS

he cutting data recommendations below are applicable to tough cemented carbide grades. These are necessary for operations in which impact may occur, such as when turning plate with gas-cut edges.

| METRIC |

Vc (m/min) |

Toolox 33

150-200 |

Toolox 40

90-140 |

Toolox 44

80-120 |

| Feed rate (fn) |

min-max |

min-max |

min-max |

| Insert grade P25 (mm/rev) |

0.20-0.40 |

0.20-0.40 |

0.20-0.40 |

At higher Feed rate , lower the cutting speed

| US |

Vc (ft/min) |

Toolox 33

492-656 |

Toolox 40

295-459 |

Toolox 44

262-394 |

| Feed rate (fn) |

min-max |

min-max |

min-max |

| Insert grade P25 (in./rev) |

0.008-0.016 |

0.008-0.016 |

0.008-0.016 |

| Formulas for turning |

Definitions |

|

Vc = cutting speed (m/min, ft/min)

n = speed (rpm)

fn = Feed rate (mm/rev, in./rev)

vf = Feed rate (mm/min, in./min)

d = workpiece Ø

π = 3,14 |

FACE MILLING RECOMMENDATION

Round inserts have strong cutting edges and are good to use when the surface has holes and cavities etc

| METRIC |

Recommendation for average machine conditions with a 45°setting angle |

| Vc (m/min) |

Toolox 33

180-220 |

Toolox 40

90-140 |

Toolox 44

120-160 |

| Feed rate (fz) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| Insert grade P30 |

0.15-0.35 |

0.25 |

0.15-0.35 |

0.25 |

0.15-0.35 |

0.25 |

| US |

Recommendation for average machine conditions with a 45°setting angle |

| Vc (ft/min) |

Toolox 33

591-722 |

Toolox 40

295-459 |

Toolox 44

394-525 |

| Feed rate (fz) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| Insert grade P30 |

0.006-0.014 |

0.010 |

0.006-0.014 |

0.010 |

0.006-0.014 |

0.010 |

| METRIC |

Recommendation for average machine conditions with round inserts |

| Vc (m/min) |

Toolox 33

180-220 |

Toolox 40

170-210 |

Toolox 44

140-180 |

| Feed rate (fz) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| Insert grade P30 |

0.10-0.25 |

0.15 |

0.10-0.25 |

0.15 |

0.10-0.25 |

0.15 |

| US |

Recommendation for average machine conditions with round inserts |

| Vc (ft/min) |

Toolox 33

591-722 |

Toolox 40

558-689 |

Toolox 44

459-591 |

| Feed rate (fz) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| Insert grade P30 |

0.000 -0.001 |

0.001 |

0.000-0.001 |

0.001 |

0.000-0.001 |

0.001 |

SHOULDER MILLING RECOMMENDATION

| METRIC |

Recommendation for average machine conditions with a 90°setting angle |

| Vc (m/min) |

Toolox 33

180-220 |

Toolox 40

140-180 |

Toolox 44

120-160 |

| Feed rate (fz) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| Insert grade P30 |

0.12-0.25 |

0.17 |

0.12-0.25 |

0.17 |

0.12-0.25 |

0.17 |

| US |

Recommendation for average machine conditions with a 90°setting angle |

| Vc (ft/min) |

Toolox 33

591-722 |

Toolox 40

459-591 |

Toolox 44

394-525 |

| Feed rate (fz) |

min-max |

start value |

min-max |

start value |

min-max |

start value |

| Insert grade P30 |

0.005-0.010 |

0.007 |

0.005-0.010 |

0.007 |

0.005-0.010 |

0.007 |

END MILLING RECOMMENDATION FOR SOLID CEMENTED CARBIDE TOOL

| METRIC |

Slot milling recommendation |

Shoulder milling recommendation |

| |

Toolox 33 |

Toolox 40 |

Toolox 44 |

Toolox 33 |

Toolox 40 |

Toolox 44 |

| Vc (m/min) |

85-110 |

75-100 |

70-95 |

200-230 |

180-210 |

160-190 |

| Feed rate (fz) |

min-max |

min-max |

min-max |

min-max |

min-max |

min-max |

| Diameter |

3.0-6.0 |

0.01-0.03 |

0.01-0.03 |

0.01-0.03 |

0.02-0.05 |

0.02-0.04 |

0.02-0.04 |

| 8.0-12.0 |

0.04-0.07 |

0.03-0.06 |

0.03-0.06 |

0.07-0.10 |

0.06-0.09 |

0.06-0.09 |

| 14.0-20.0 |

0.07-0.10 |

0.06-0.09 |

0.06-0.08 |

0.10-0.14 |

0.10-0.13 |

0.10-0.12 |

* If possible, use only compressed air to remove the chip and use weldon chuck for tool over Ø 10.

| US |

Slot milling recommendation |

Shoulder milling recommendation |

| |

Toolox 33 |

Toolox 40 |

Toolox 44 |

Toolox 33 |

Toolox 40 |

Toolox 44 |

| Vc (ft/min) |

279-361 |

246-328 |

230-312 |

656-755 |

591-689 |

525-623 |

| Feed rate (fz) |

min-max |

min-max |

min-max |

min-max |

min-max |

min-max |

| Diameter |

0.118-0.236 |

0.000-0.001 |

0.000-0.001 |

0.000-0.001 |

0.001-0.002 |

0.001-0.002 |

0.001-0.002 |

| 0.315-0.472 |

0.002-0.003 |

0.001-0.002 |

0.001-0.002 |

00.003-0.004 |

0.002-0.004 |

0.002-0.004 |

| 0.551-0.787 |

0.003-0.004 |

0.002-0.004 |

0.002-0.003 |

0.004-0.006 |

0.004-0.005 |

0.004-0.005 |

Slot milling advice

ap (depth of cut) max 0.5 x D

Shoulder milling advice

ap (use the whole cutting length)

ae (radial depth of cut) max 0.1 x D

TAPPING RECOMMENDATIONS

With the correct tools you can perform all tapping/thread milling operations using all Toolox grades. We recommend four-flute taps, which can withstand the very high torque that occurs during tapping in hard materials. If is not critical, the drilled hole can be 3% larger than standard. This will increase the lifetime of the tap.

* Thread oil or thread paste is recommended as lubricant.

| METRIC |

Vc (m/min |

Toolox 33

7-10 |

Toolox 40

4-9 |

Toolox 44

3-5 |

| US |

Vc (ft/min) |

Toolox 33

23-33 |

Toolox 40

13-30 |

Toolox 44

10-16 |

| Size |

Speed ( rpm ) |

Speed ( rpm ) |

Speed ( rpm ) |

| M5 |

445-635 |

255-570 |

190-320 |

| M6 |

370-530 |

210-475 |

160-265 |

| M8 |

270-400 |

160-360 |

120-200 |

| M10 |

220-320 |

125-285 |

95-160 |

| M12 |

185-265 |

105-240 |

80-130 |

| M16 |

140-200 |

80-180 |

60-100 |

| M20 |

110-160 |

60-140 |

45-80 |

* We recommend thread milling for thread below M5 especially in Toolox 40 and 44.

| METRIC |

|

Toolox 33 |

Toolox 40 |

Toolox 44 |

| Vc (m/min |

80-110 |

60-80 |

50-70 |

| fz mm |

0.03-0.06 |

0.02-0.05 |

0.02-0.05 |

* To manage thread milling, a CNC machine is necessary and the thread should be made in 2 passes.

| US |

|

Toolox 33 |

Toolox 40 |

Toolox 44 |

| Vc (ft/min) |

263-361 |

197-263 |

164-230 |

| fz (in.) |

0.001-0.002 |

0.001-0.002 |

0.001-0.002 |

COUNTERSINKING & COUNTERBORING

Countersinking and counterboring are best performed using tools that have replaceable inserts. Always use a revolving pilot and use coolant.

| METRIC |

Vc ( m/min ) |

Toolox 33

40 - 80 |

Toolox 40

25 - 70 |

Toolox 33

20 - 50 |

| Feed rate (mm/rev) |

0.10-0.20 |

0.10-0.20 |

0.10-0.20 |

| Dc (mm) |

Speed ( rpm ) |

| 19 |

670-1340 |

420-1175 |

335-840 |

| 24 |

530-1060 |

330-930 |

265-665 |

| 34 |

375-750 |

235-655 |

185-470 |

| 42 |

300-600 |

190-530 |

150-380 |

| 57 |

225-440 |

140-390 |

110-280 |

* Reduce the cutting data by about 30 % in countersinking.

| US |

Vc (ft/min) |

Toolox 33

131-262 |

Toolox 40

82-230 |

Toolox 33

66-164 |

| Feed rate (mm/rev) |

0.004-0.008 |

0.004-0.008 |

0.004-0.008 |

| Dc (in.) |

Speed ( rpm ) |

| 0.748 |

670-1340 |

420-1175 |

335-840 |

| 0.945 |

530-1060 |

330-930 |

265-665 |

| 1.339 |

375-750 |

235-655 |

185-470 |

| 1.654 |

300-600 |

190-530 |

150-380 |

| 2.244 |

225-440 |

140-390 |

110-280 |

RESULTS FROM OUR OWN TESTS

MACHINE INFO

VMC FADAL 4020 HT modell 1997

Spindle type ISO 40 tape

Through spindle coolant

Spindle speed max 10,000 rpm

Effect on the spindle motor 16.8 kw

Torque 303 Nm.

| Toolox 33 |

Tool |

Ø |

Vc |

f |

ap |

ae |

runtime |

| Shoulder milling |

Coromill 490 |

50 mm |

180 m |

0.17 mm |

4 mm |

13 mm |

196 min |

| |

|

1.969 in. |

591 ft. |

0.007 in. |

0.157 in. |

0.512 in. |

196 min |

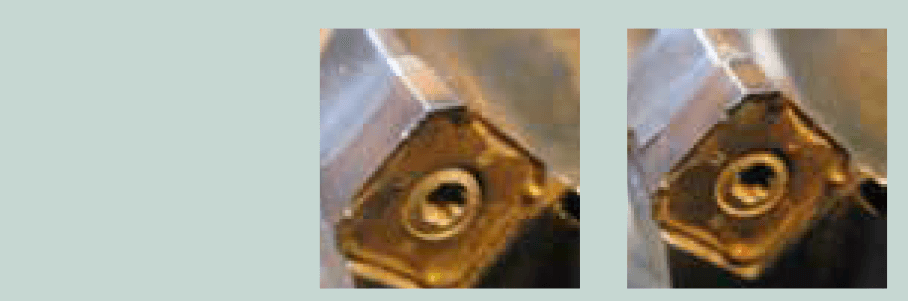

| Runtime 132 min |

Runtime 196 min |

|

|

| Toolox 40 |

Tool |

Ø |

Vc |

f |

ap |

ae |

runtime |

| Face milling |

Coromill 490 |

100 mm |

160 m |

0.25 mm |

2 mm |

68 mm |

43 min |

| |

|

3.937 in. |

525 ft. |

0.010 in. |

0.079 in. |

2.677 in. |

43 min |

|

|

| Toolox 44 |

Tool |

Ø |

Vc |

f |

ap |

ae |

runtime |

| Face milling |

Coromill 345 |

100 mm |

150 m |

0.25 mm |

2 mm |

61 mm |

32 min |

| |

|

3.937 in. |

492 ft. |

0.010 in. |

0.079 in. |

2.402 in. |

32 min |

|

|

| Toolox 44 |

Tool |

Ø |

Vc |

f |

ap |

ae |

runtime |

| Shoulder milling |

End milling |

16 mm |

180 m |

0.12 mm |

34 mm |

1.6 mm |

103 min |

| |

|

0.630 in |

591 ft. |

0.005 in |

1.339 in. |

0.063 in. |

103 min |

|

|

| Toolox 33 |

Tool |

Ø |

Vc |

fn |

total |

drill depth |

coolant flow |

| Drilling/ blind holes |

Corodrill 840 |

6.8 mm |

80 m |

0.12 mm |

1105 |

23 mm |

1.9 l/min |

| |

|

0.630 in. |

591 ft. |

0.005 in. |

|

0.906 in. |

0.502 GPM |

|

|

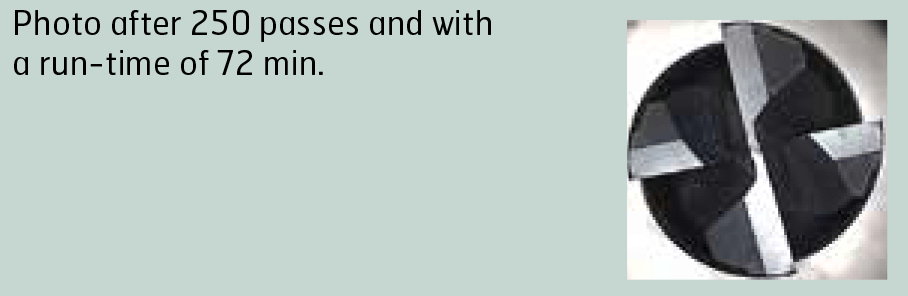

| Toolox 40 |

Tool |

Ø |

Vc |

fn |

total |

drill depth |

coolant flow |

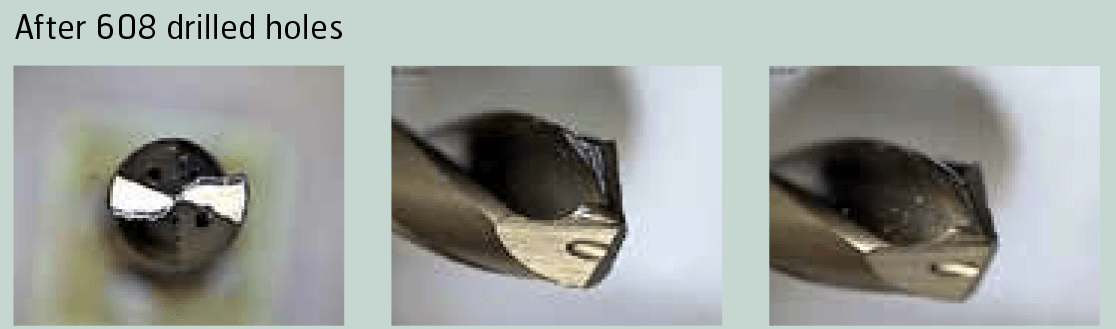

| Drilling/ blind holes |

Seco Feedmax |

4.3 mm |

70 m |

0.12 mm |

608 |

16 mm |

0.2 l/min |

| |

|

0.169 in. |

230 ft. |

0.005 in. |

|

0.630 in. |

0.053 GPM |

|

|

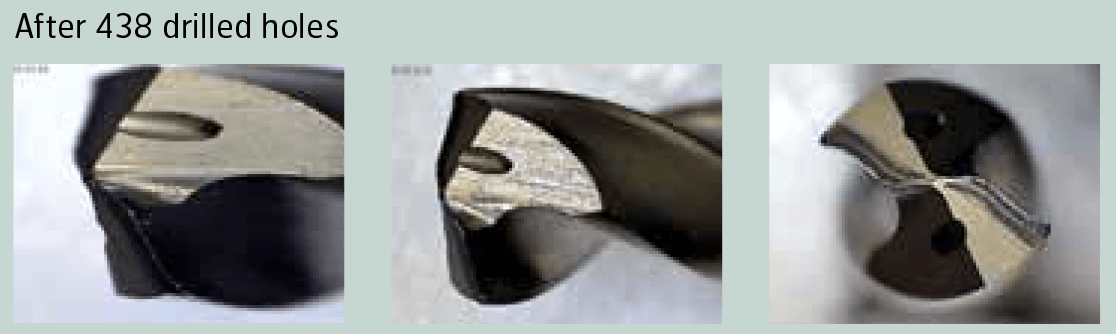

| Toolox 44 |

Tool |

Ø |

Vc |

fn |

total |

drill depth |

coolant flow |

| Drilling/ blind holes |

Seco Feedmax |

4.3 mm |

60 m |

0.06 mm |

438 |

15 mm |

0.21 l/min |

| |

|

0.169 in. |

197 ft. |

0.002 in. |

|

0.591 in. |

0.053 GPM |

|

|

| Toolox 40 |

Tool |

drill Ø |

Ø |

Vc |

thread

depth |

Total |

| Tapping / blind holes |

Manigley 131/3 DUO |

4.3 mm |

M5 |

11 m |

12 mm |

330 |

| |

|

0.169 in. |

M5 |

36 ft. |

0.472 in. |

330 |

| Toolox 40 |

Tool |

drill Ø |

Ø |

Vc |

thread

depth |

Total |

| Tapping / blind holes |

Manigley 131/3 DUO |

10.2 mm |

M12 |

8 m |

24 mm |

217 |

| |

|

0.402 in. |

M12 |

26 ft. |

0.945 in. |

217 |

| Toolox 44 |

Tool |

drill Ø |

Ø |

Vc |

thread

depth |

Total |

| Tapping / blind holes |

Manigley 131/3 DUO |

4.3 mm |

M5 |

3 m |

10 mm |

183 |

| |

|

0.169 in. |

M5 |

10 ft. |

0.394 in. |

183 |

|

|

| Toolox 40 |

Tool |

drill Ø |

Ø |

Vc |

thread

depth |

Total |

| Tapping / blind holes |

Manigley 131/3 DUO |

14.2 mm |

M16 |

6 m |

25 mm |

276 |

| |

|

0.560 in. |

M16 |

20 ft. |

0.984 in. |

276 |

|

|

TOOL RECOMMENDATIONS FOR TOOLOX

DRILLING IN TOOLOX

| Tool name |

Article No. |

Diameter range |

Seco

Feedmax |

* SD203A-12.0-36-12R1 |

2.0-20.0 mm

(0.079-0.787 in.) |

| Tool name |

Article No. |

Diameter range |

Seco

Feedmax |

* SD216A-12.0-180-12R1 |

3.0-14.10 mm

(0.118-0.555 in.) |

Long holes drilling with 16-20xD

Solid cemented carbide drill

Supplier: Seco

Sweden

www.secotools.com

| Tool name |

Article No. |

Diameter range |

Cordrill R840

Delta C |

R840-xxxx-30-A1A |

3.0-20.0 mm

(0.118-0.787 in.) |

| Tool name |

Article No. |

Diameter range |

| Chamdrill |

* SD103-12.00-40-16R7 |

0.0-25.99 mm

(0.394-1.023 in.) |

Drill with exchangeable drill heads

Drill heads grade: P

Supplier: Seco

Sweden

www.secotools.com

| Tool name |

Article No. |

Diameter range |

| Chamdrill |

DCM xxx-xxx-xxA-xx.xx |

7.5-25.9 mm

(0.295-1.020 in.) |

Drill with exchangeable drill heads

Drill heads grade: IC908

Supplier: Iscar

Israel

www.iscar.com

| Tool name |

Article No. |

Diameter range |

HSS -E Co 8 Taper

Shank Drills, WN

103 |

832xxxxx |

8.0-40.0 mm

(0.315-1.575 in.) |

High-speed steel drill alloyed with

8 % cobalt (HSS-Co 8 %)

Supplier: Alpen-MayKestag

Austria

www.alpenmaykestag.com

TAPPING IN TOOLOX

Tap for blind holes

| Tool name |

Article No. |

Diameter range |

| 1641 TC |

1641TC Mxx |

18.0-75.0 mm

(0.709-2.953 in.) |

HSS-P tap with TiCN coating

Supplier: Yamawa

Sweden

www.yamawa.eu

Tap for through holes

| Tool name |

Article No. |

Diameter range |

| 105/4 DUO |

433xx |

20.5-60.0 mm

(0.807-2.362 in.) |

HSSE-PM tap with TiCN coating

Supplier: Manigley

Switzerland

www.manigley.ch

Tap for blind holes

| Tool name |

Article No. |

Diameter range |

| 131/3 DUO |

433xx |

3.0-25.0 mm

(0.118-0.984 in.) |

HSSE-PM tap with TiCN coating

Supplier: Manigley

Switzerland

www.manigley.ch

Tap for blind holes

| Tool name |

Article No. |

Diameter range |

| Rekord 1D-TI-TiCN |

B0459601.xxxx |

M3-M10 |

| Rekord 2D-TI-TiCN |

C0459601.xxxx |

M12-M24 |

Tap for through holes

| Tool name |

Article No. |

Diameter range |

| Rekord 1C-Ti-TiCN |

B0309601.xxxx |

M3-M10 |

| Rekord 2C-Ti-TiCN |

C0309601.xxxx |

M12-M24 |

THREAD MILLING IN TOOLOX

| Tool name |

Article No. |

Diameter range |

GSF-VHM 2xD

IKZ-HB TiCN |

GSF333106xxxx |

M3-M16 |

Solid carbide thread milling cutter

with TiCN coating

Supplier: Emuge Franken

Germany

www.emuge.de/english

| Tool name |

Article No. |

Diameter range |

Solid carbide

thread mill |

NBxxxxxCxx

x.xISO AC |

M2-M42 |

Solid carbide thread milling

cutter with TiAlCN coating

Supplier: SmiCut

Sweden

www.smicut.se

COUNTERBORING IN TOOLOX

Use counterbore with indexable inserts that always have a grade number ending in H

| Tool name |

Article No. |

Diameter range |

| WHV counterbore |

XWHV-xx.x |

18.0-75.0 mm

(0.709-2.953 in.) |

COUNTERSINKING IN TOOLOX

Use countersink with indexable inserts that always have a grade number ending in H

| Tool name |

Article No. |

Diameter range |

| KV countersink |

xKV9-xx.x |

20.5-60.0 mm

(0.807-2.362 in.) |

END MILLING IN TOOLOX

| Tool name |

Article No. |

Diameter range |

| KV countersink |

xKV9-xx.x |

20.5-60.0 mm

(0.807-2.362 in.) |

Solid end milling cutter with Siron-A coating

Supplier: Seco

Sweden

www.secotools.com

MILLING WITH INSERT IN TOOLOX

| Tool name |

Article No. |

Diameter range |

| Coromill 345 |

345-xxxxxx-13x |

40-250 mm

(1.575-9.843 in.) |

| Tool name |

Article No. |

Diameter range |

| Coromill 300 |

R300-xxxxxx-xxx |

10-200 mm

0.394-7.874 in.) |

| Tool name |

Article No. |

Diameter range |

| Coromill 490 |

490-xxxxx-xxx |

20-250 mm

(0.787-9.843 in.) |

| Tool name |

Article No. |

Diameter range |

| Coromill 490 |

490-xxxxx-xxx |

20-250 mm

(0.787-9.843 in.) |

INSERT GRADE IN TOOLOX

| Tool name |

Article No. |

Insert grade |

Insert

geometry |

| Coromill 300 |

R300-xxxxx-Px |

1010 |

L-M-H |

| R300-xxxxx-Px |

1030 |

L-M-H |

| Coromill 345 |

345R-1305x-Px |

1010 |

L-M-H |

| 345R-1305x-Px |

1030 |

L-M-H |

| Coromill 490 |

490R-xxxxxxx-Px |

1010 |

L-M |

| 490R-xxxxxxx-Px |

1030 |

L-M-H |

Use insert grade P1030 for average machine conditions. In very stable machine conditions and with a rigid set-up, insert grade P1010 is more suitable, especially in Toolox 40 and 44. Then you can increase the cutting speed by approximately 20-30%.

Supplier: Sandvik Coromant AB

Sweden

www.sandvik.coromant.com

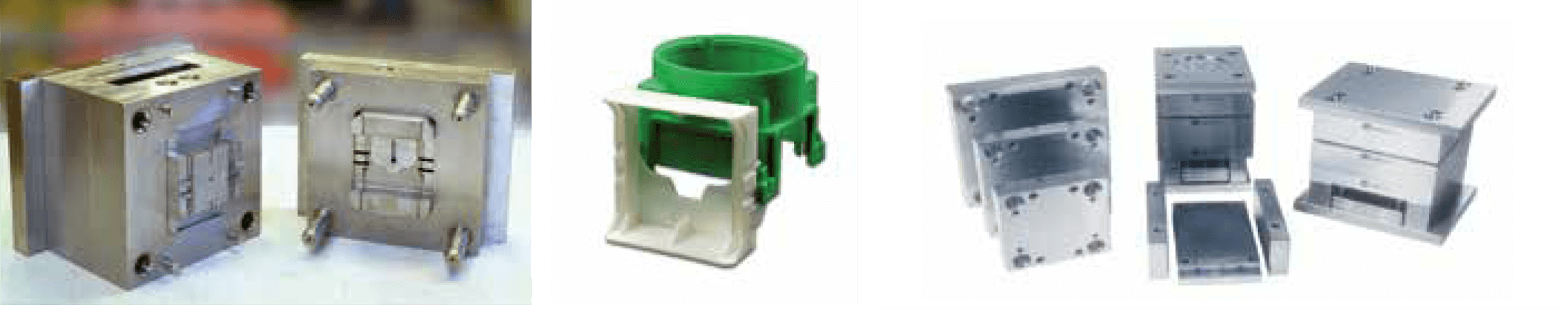

APLICATION AREAS

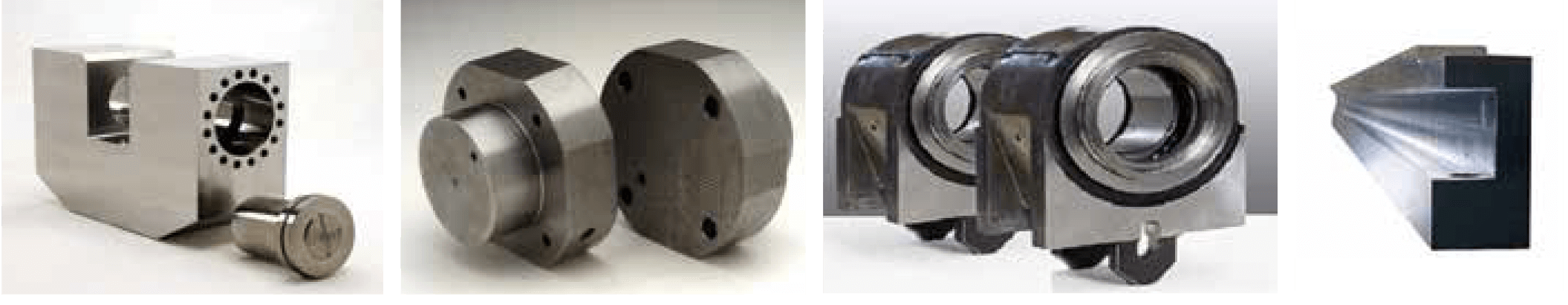

MOULDS

COLD WORK

HOT WORK

MACHINE COMPONENTS