LASER HARDENING OF TOOLOX®

Toolox® is an excellent steel for the production of high performance dies and machine components. Toolox® is based on an ultra-clean steel metallurgical concept that gives it extraordinary properties. A combination of high strength, crack resistance and optimized workshop properties make it an ideal choice in situations with the highest demands. The guaranteed toughness as well as the plate per plate quality control minimizes the risk for early failures.

For some applications, the surface properties need to be further improved. In such cases, laser hardening has been shown to be a very efficient method, giving a high surface hardness with a relatively large thickness. The combination of laser hardening and Toolox® 44 is especially interesting due to the uniquely high yield strength of Toolox®. Below the laser hardened layer there will be a very resistant material. Laser hardened surfaces have the further advantage of being very smooth. This reduces friction and the risk for material sticking to the surface.

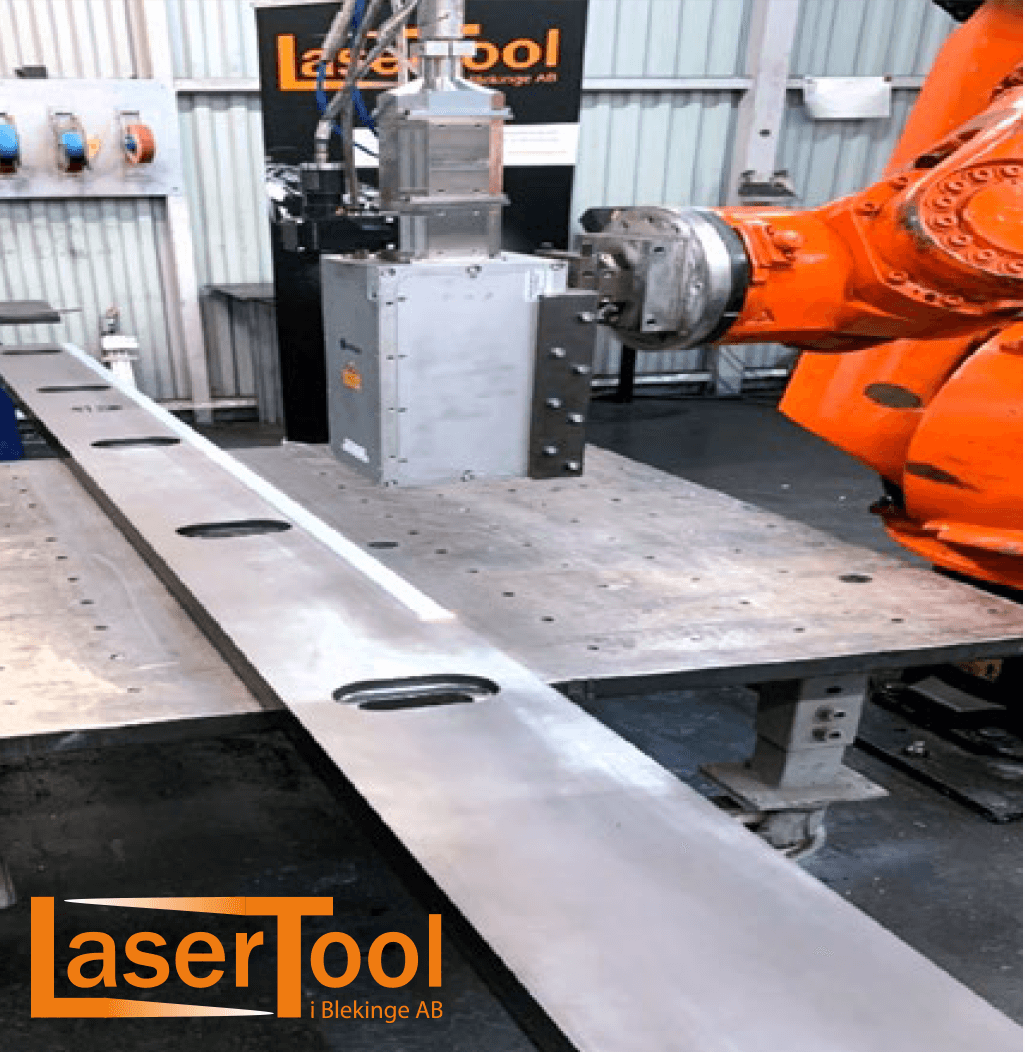

To increase the knowledge of the laser hardening behavior of Toolox®, testing and application develop ment has been made in cooperation with this Swedish Laser hardening specialist LaserTool in Blekinge AB (www.lasertool.com). LaserTool in Blekinge AB has since 2003 been pioneering the usage of laser hardening. Since then they have been proven a cutting-edge supplier for many different types of applications, including cold forming dies and advanced machine parts.

LaserTool is using a fiber coupled diode laser with 4kW output. To further enhance the hardness in the surface a carbon powder is used to cover the metal surface during the process. In this way, the surface hardness of Toolox® 44 can be boosted to 800 HV. For Toolox® 33, 700 HV can be obtained. Thicknesses of 0.2 to 2 mm is chosen depending on the application.

Figure 1. Laser hardening of Toolox® 44 has been used for several types of components. An excellent application is cold forming dies. The die used for stamping thick steel sheet, shown in Figure 1, was previously made in tool steel heat treated to 60 HRc. Cracking after 2000-3000 stampings made that solution unsuitable. Changing to laser hardened Toolox® 44 improved the lifetime to more than 100 000 stampings. The smooth surface also decreases the need for maintenance.

Figure 2. Another successful application is a bushing used in a shot blasting machine, seen in Figure 2. Around the bushing, a shovel wheel is placed. The wear from the wheel and the environment inside the machine represents severe conditions making laser hardening a perfect method to improve lifetime.

Figure 3. For machine components working under the most demanding conditions, laser hardening improves lifetime. SSAB is using laser hardened Toolox® 44 for cutting Hardox® and Strenx® steel plates. The shearing blades are seen in figure 3. A high hardness and strength are due to the thickness and high hardness of the products.

Availability

Plates from 6 – 165 mm. Bars between 16 and 353 mm with lengths up to 5000 mm. Toolox® is available from the local SSAB stock. Cut pieces of Toolox® can be obtained through the well-established global network of Approved Toolox® Distributors. Both SSAB and Toolox® distributors can also provide you with good application support as well as technical guidelines.

Contact and more information

Contact your local sales representative to learn more, visit www.toolox.com or consult Tech Support at: [email protected]